Why should I buy anything other than counterfeit network cable, which is

cheaper? Yes, you can save money by using a low-grade cable on an installation,

but does it really translate in to savings or cost you more money in the long

run?

Let’s take a look at the evidence of time. It seems as if every time the

price of counterfeit copper or other cable components increases that a new wave

of fake/counterfeit products hits the market place. Once installed someone

eventually gets caught.

Datcom has been monitoring and reporting these incidences over the years

as these issues arise. Lately the frequency of occurrences has increased. We

have encountered products in June 07, April 09, Aug 10, Oct 10, and was reported

as a growing concern in the Feb 2011

reported in Cabling and Maintenance a popular industry magazine. Fast

forward to 2015 a we now have a whole association; CCCA in place to combat this insidious issue.

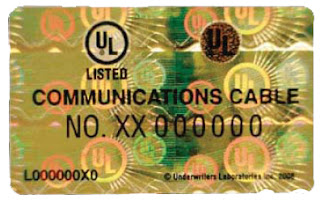

This problem has prompted UL

to integrated similar holographic technology used on credit cards to try

and stem the flow of this type of product. You can protect yourself and verify

products using the itunes Authenticator

App.

But

here are the real issues when the cable is always discovered:

1) Cables seldom

pass the standards.

2) Intermittent

problems occur resulting in unscheduled service calls.

3) If an

inspection is done it usually leads to a total re-install at the contractors

expense

4) Potential loss

of a client due to a perception of poor quality work.

5) Proliferation

of low quality products in the market place.

6) No point of

presence or local manufacturer support.

7) Zero product

constancy.

8) No

compensation when problems arise.

Most non-branded products are a scam

and are here today but gone tomorrow. If you have never heard of the brand

before, then rule of thumb says don't buy it no matter what the price.

End users are responsible for hiring

contractors that know what they are doing. Contractors are responsible for

dealing with distributors who are reliable, and distributors are responsible

for dealing with manufactures that stand behind their products. If all else

fails plug the UL number into the online directory and make sure the cable is

listed for use in the country of purchase and what regulations it meets. The bottom line

is that you get what you pay for & you should be buying from a reputable

distributor.

For more information on cable or other products call

1-800-427-2055.